AOT BENEFITS

CONFIGURABLE TO CUSTOMER SPECIFICATIONS

MODULAR SCALABLE VERSATILE

FROM SINGLE TO MULTIPLE UNIT INSTALLATIONS

Originally a design concept used to create educational excellence from flexibility,

It is the modularity of the Applied Oil Technology system – allowing every unit to work singly or in a combined function – which is its key feature in enhancing versatility and adaptability.

AOT components can be seamlessly integrated into existing operations, making it a flexible solution for hydrocarbon transportation systems worldwide.

Whether upgrading a system or implementing targeted improvements, AOT’s modular design allows operators to tailor its deployment to their specific flowrate needs.

This adaptability ensures efficient viscosity reduction, increased pipeline capacity, and reduced power consumption, all while minimizing disruption to existing infrastructure.

AOT

- Footprint of 65 ft2 and height of 33 ft

- Weight is 20 tons excluding headers

- ASME VIII 1440 pressure rating (100°f or less)

- Skid mounted for vertical or horizontal installation

- Engineered concrete pad required for installation

- Cathodic protection of pipeline not compromised

- Header supplied by customer

POWER SUPPLY

- Requires 480 VAC or 208 VAC 3 phase power

- Air conditioned NEMA Box

- Concrete pad preferred but not required

- Room for SCADA equipment

- High voltage cables supplied by QS Energy up to 100’ in length

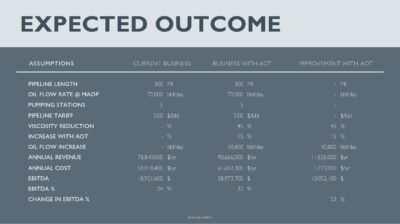

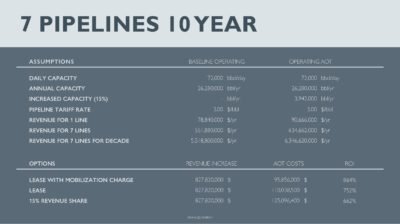

OPERATIONAL EFFICIENCIES

CONFIGURABLE TO CUSTOMER SPECIFICATIONS

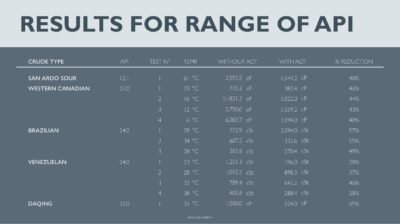

Through significant reductions in viscosity, AOT has effected a revolution in how we manage hydrocarbon pipelines.

And into the loading and unloading of tankers, trains and trucks, the revolution has brought all of AOT’s abundant and corresponding benefits to scale.

- Boosts Maximum Flow Rates: AOT ensures smoother flow, allowing pipelines to handle higher volumes efficiently.

- Lowers Operating Pressures: by reducing viscosity, AOT minimizes the pressure needed.

- Facilitates Unloading of Tankers: by lowering the viscosity, AOT reduces time spent uploading.

- Eliminates or Minimizes Bottlenecks: AOT streamlines flow, preventing congestion points and enhancing throughput.

- Reduces Pump Station Power Consumption and CO2 Emissions: energy-efficient AOT contributes to a greener environment.

- Carbon Credit and Tax Benefits: implementing AOT can lead to reduced emissions and improved energy efficiency.