OIL TEST RESULTS

LABORATORY FINDINGS OF GREAT POTENTIAL

THE VISCOSITY PROBLEM

Applied Oil Technology represents the history and rationale of a breakthrough unfolded over 20 years.

It was invented, tested exhaustively and finalised in order to serve an industry whose central and defining issue has always been the viscosity of oil and the necessarily good management of it.

Whatever the grade, midstream or upstream, from extraction to refinement and throughout production and transportation, there has always been the same coagulated adversary to be overcome as cost effectively as possible.

The viscosity problem is ubiquitous. Traveling through the pipelines, its resistance to flow increases operational costs, reduces efficiency and poses safety risks. Mitigation methods have involved additives or diluents but these solutions come at a price and often introduce unwanted side effects.

Across the decades engineers have spared no effort to improve the flow of oil and to reduce its clinging to the pipelines but, despite some progress, the slowed flow and delays remained, typically contributing to bottlenecks.

OIL TEST PROTOCOL

TEMPLE’s FIVE STEPS: SIMPLICITY AND ACCURACY

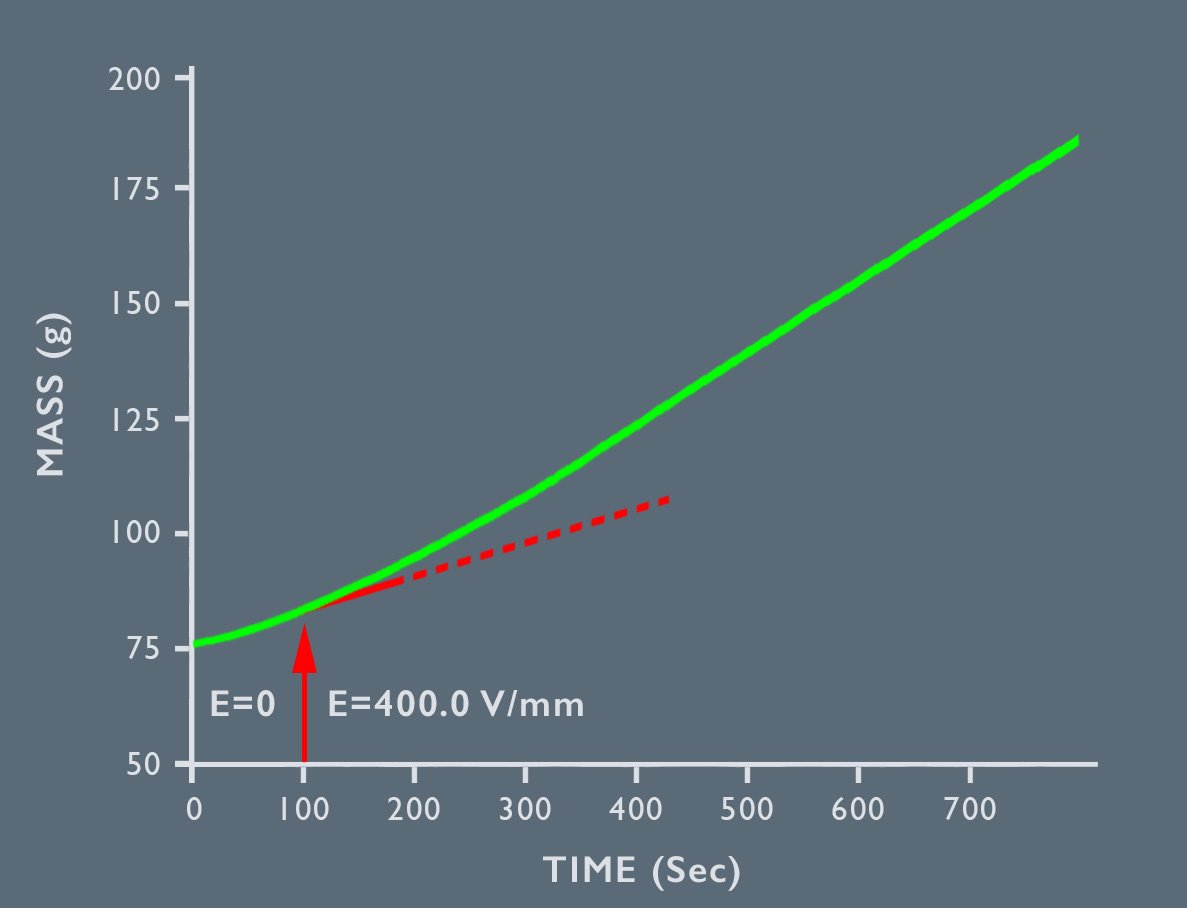

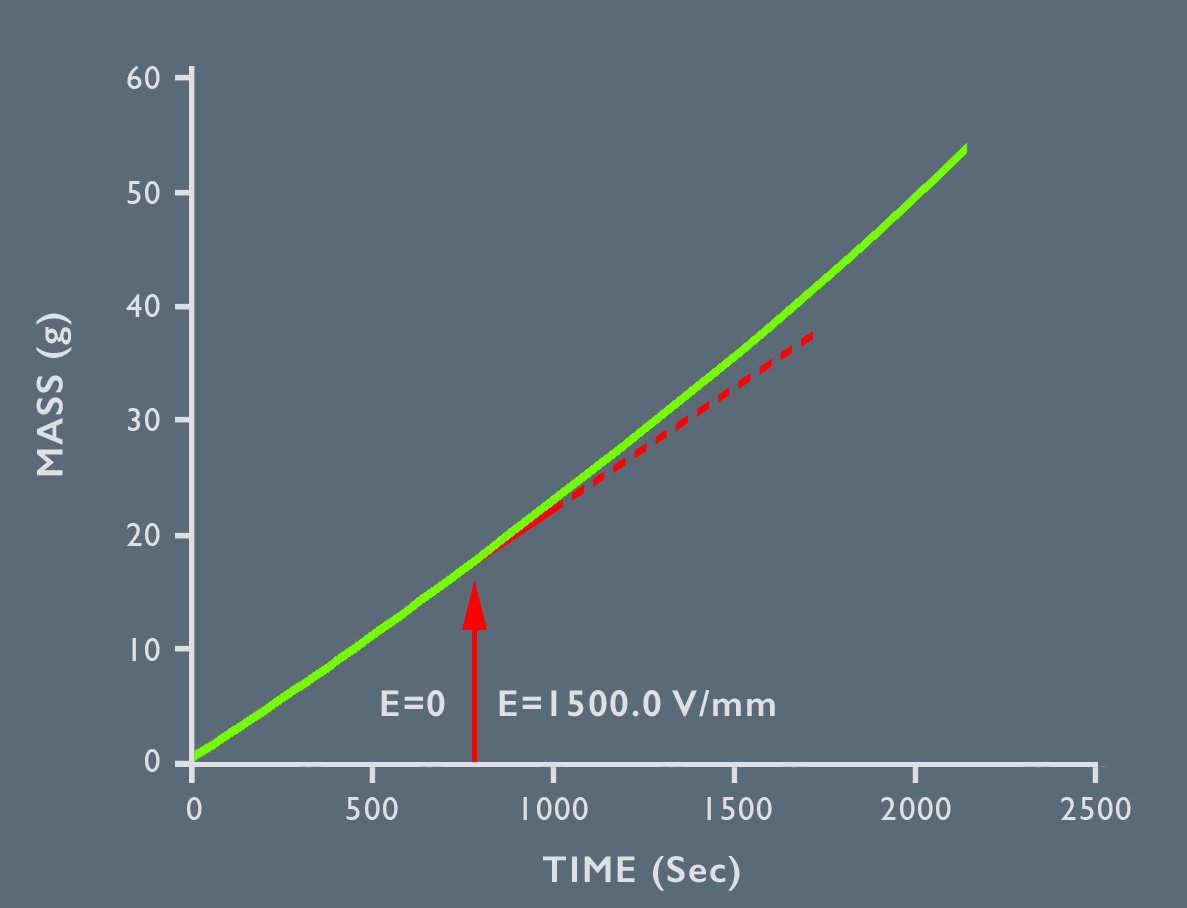

The setup: the complexity of Viscosity broken down to simplest elements starts with a cylinder serving as a reservoir for the oil sample placed in an environment chamber. Three meshes act as electrodes connected to a low amperage, high voltage power supply. The crude oil flows through the electrodes into a capillary tube with a beaker collecting the oil below.

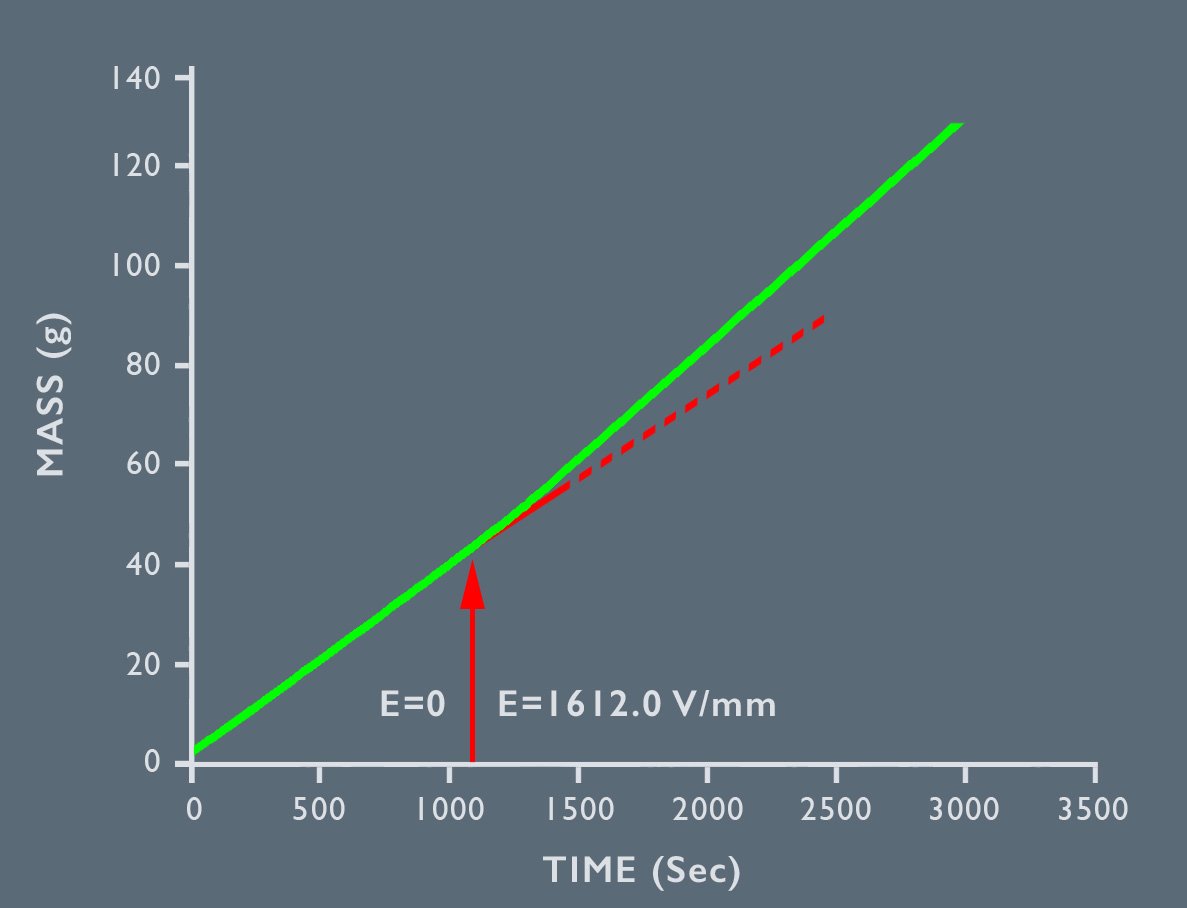

Measurement: a microbalance connected to a computer records the oil mass in the beaker and with LabVIEW software measuring the flow rate accurately in real time.

Electric Field Application: when the power supply is turned on, a strong electric field is generated in the flow direction of crude oil, causing suspended particles to aggregate into streamlined short chains anisotropically along the flow direction. This reduces the effective viscosity of the crude oil without the need for heating, drag reducing agents, or diluents.

Viscosity Determination: the capillary tube functions as a viscometer. The flow rate is used to mathematically determine the viscosity. Initially, the flow rate is measured without the electric field to obtain the viscosity of the untreated oil. Then, the electric field is turned on, a new flow rate is measured, and the viscosity of the electric-field treated crude oil is determined. The electric field strength can be adjusted to reach the optimal state for viscosity reduction.

Results: the viscosity reduction and resulting flow rate improvements have the potential to significantly enhance tariff revenue when the technology is implemented commercially.

VISCOSITY REDUCTION

DRAMATIC RESULTS FOR TARGET OILS

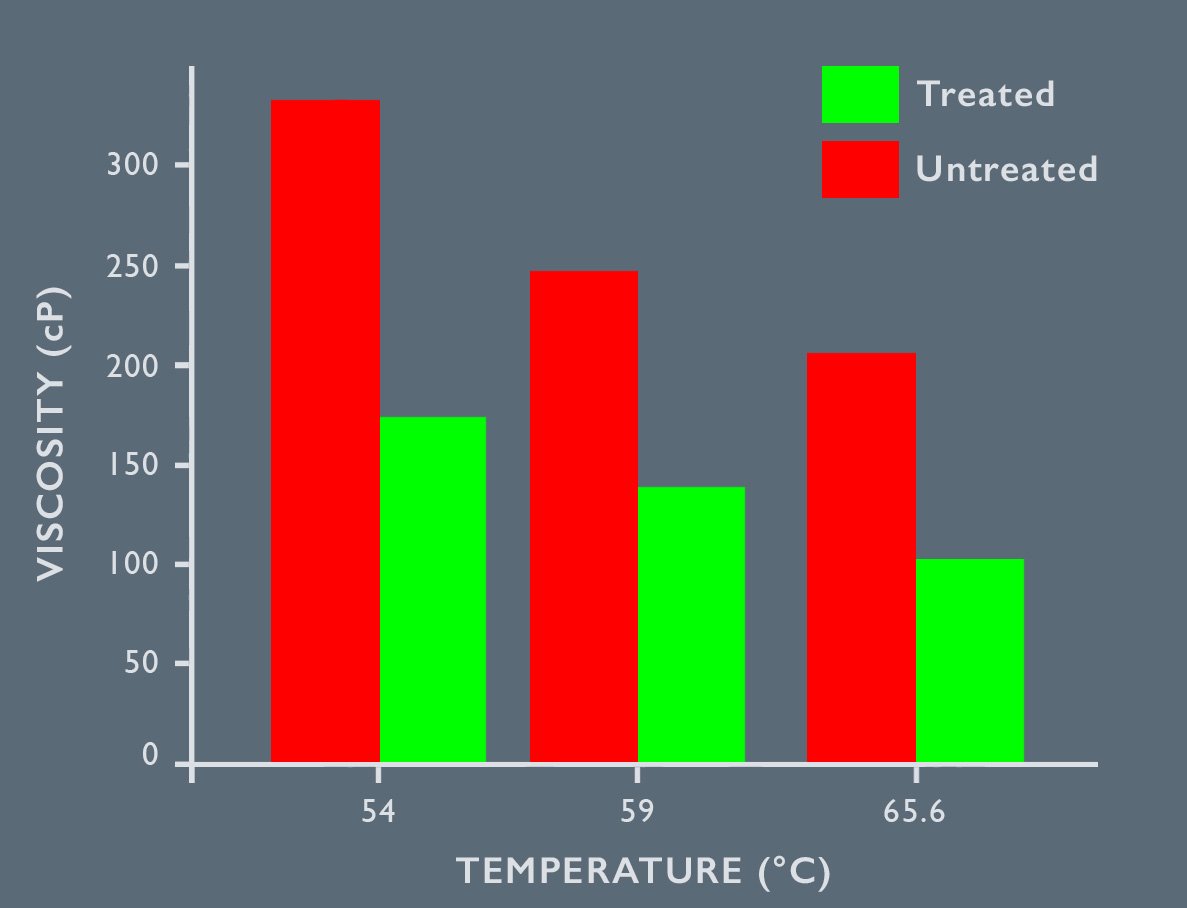

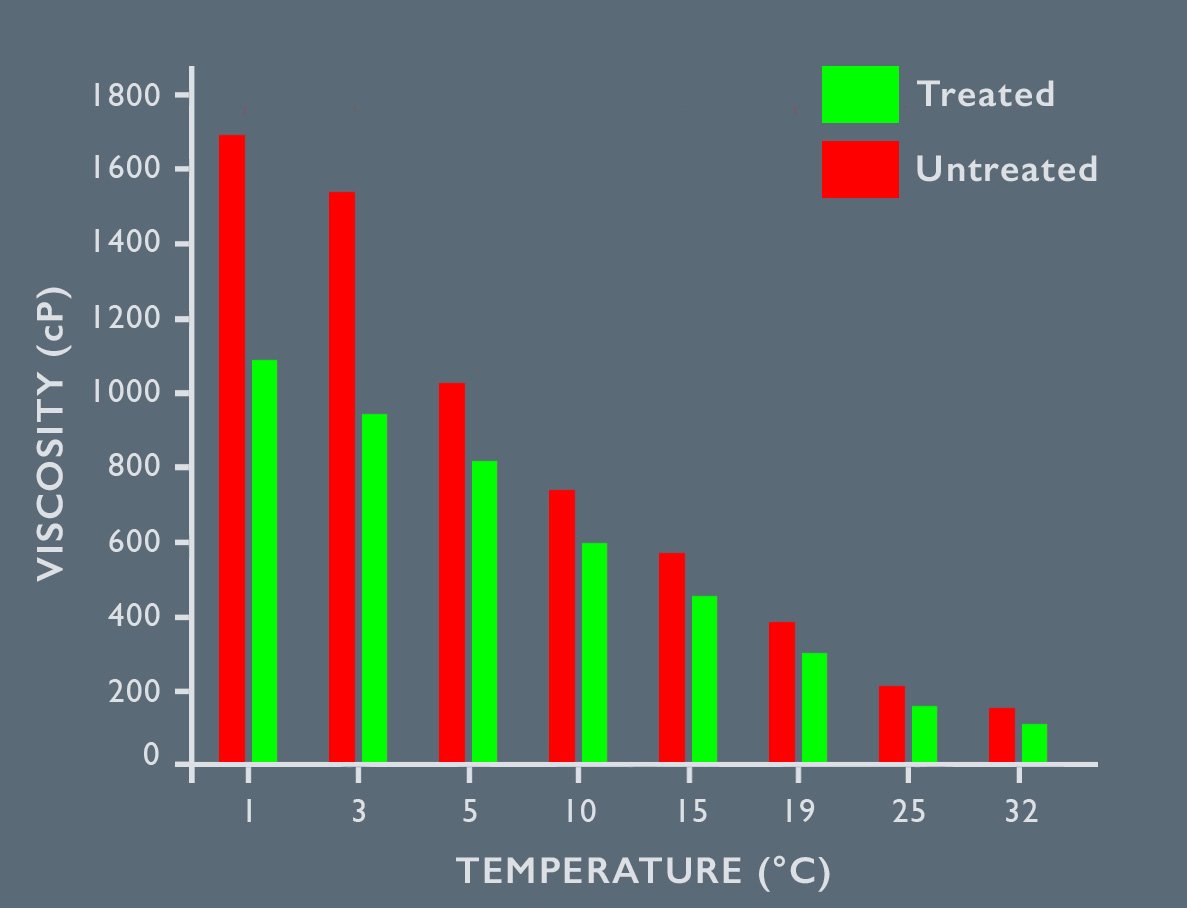

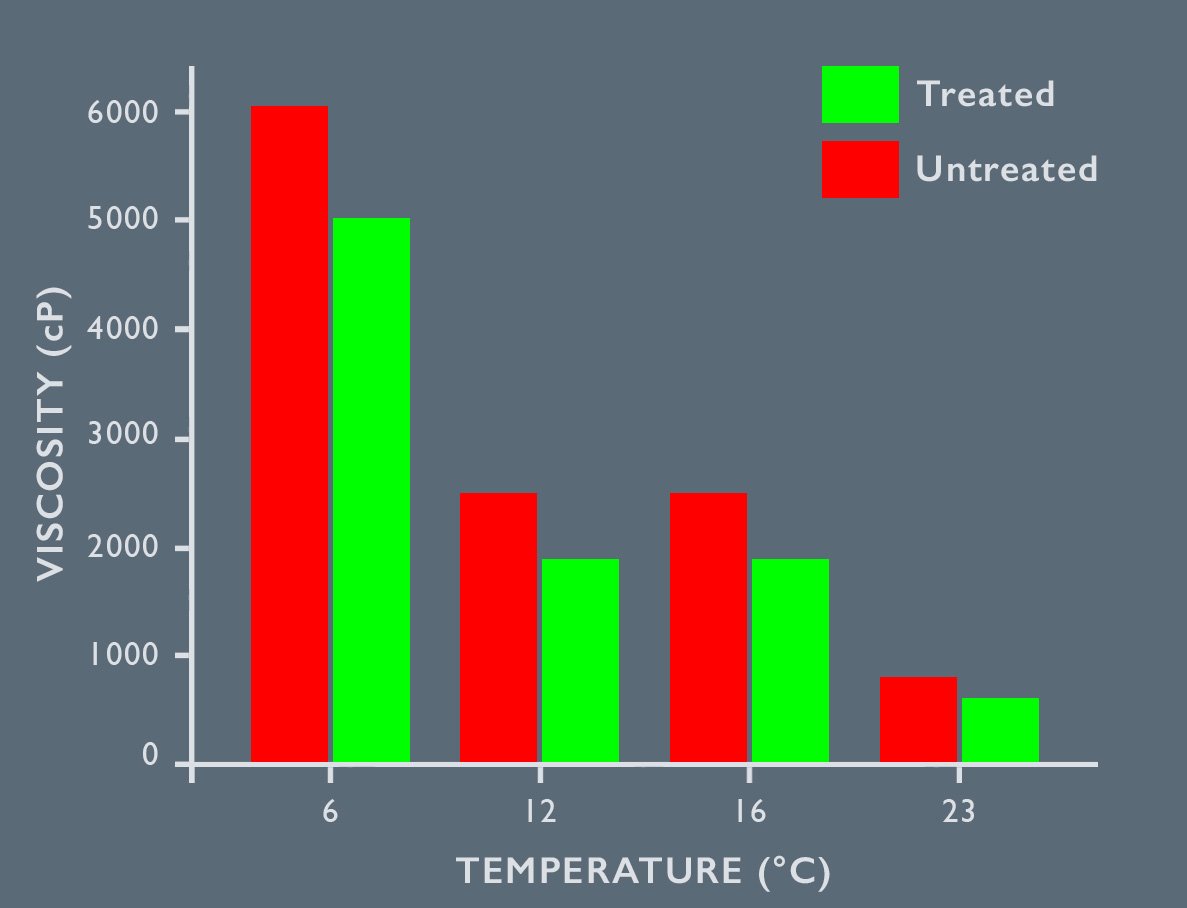

In all tests the AOT treatment significantly reduced viscosity relative to the untreated oil samples.

- Medium to Heavy Crude: a remarkable 50% viscosity reduction consistenly achieved.

- Heavy Crude: approximately 40% improvement demonstrated.

- Waxy Crude: over 60% recorded.

- Hydrocarbons with Low Particulates (e.g., Diesel): the most modest gain of less than 5% established.

Below, a global selection of oil sample test results demonstrates considerable reductions in viscosity, showcasing to prospective clients the impressive percentage decreases achieved by AOT.

ALBERTA

SAUDI ARABIA

BRAZIL OFFSHORE

CALIFORNIA

DAQING

GHANA

NEW MEXICO

ECUADOR

STRATEGIC DATA INTELLIGENCE

LABORATORY INTEGRAL TO CLIENT PLANNING

Temple laboratory data is essential for optimizing client business plans, providing insights crucial for quality, efficiency and compliance.

Analyzing this data, always presented graphically like the sample reports shown here, enables our clients to pinpoint areas for improvement, identify potential benefits and make informed decisions swiftly.

Accurate data drives strategic planning and operational excellence. It empowers midstream and upstream clients to adapt to market demands, minimize environmental risks and achieve their financial goals confidently. To fully understand the benefits of the AOT, please read the Expected Outcome section in the AOT Benefits page.