Upcoming Component Testing

In our April 15, 2022, Investor Update we summarized how the results of the AOT component testing resulted in a set of design criteria for the new stack assembly and the success of identifying alternate materials of construction. Recently, we have been working to reduce those findings to practice. We are now moving forward to the following three steps:

- Complete testing of the component stack assembly.

- A full-size hydrostatic test of the AOT.

- A field test with a development partner.

Our focus for this update is concerning the pending component tests. These tests are an important step validating newly designed parts minimizing both cost and time. We have seen before; the absence of a successful testing program can lead to an unintended failure. The follow up hydrostatic test is designed to run a fully assembled AOT at near operational conditions. Since we are not installed on a pipeline, we will lack flow and pressure, but all other factors will be the same as a customer installation. Lastly, a field test with a development partner would be under both flow and pressure as final validation of the AOT. As we have not seen mechanical issues due to flow or pressure a successful hydrostatic test should be a good predictor of a successful field test. Therefore, the field test will be focused on validation of the beneficial effect of AOT on pipeline crude oil.

The component test is designed to validate the new stack assembly’s ability to address the 7 design criteria shared in the April 15, 2022, Investor Update. The new stack assembly addresses the 7 seven design criteria in the following ways:

- All metal surfaces will have rounded edges.

- All perpendicular surfaces between grids have been eliminated.

- Grids are better supported and will have a uniform separation.

- All electrical connections will have positive mechanical contact.

- All corners have been removed from the grid design.

- The entire perimeter of the grids are now surrounded with insulation.

- Two new materials have been selected for insulation, and the blind design will be less sensitive to insulation swelling.

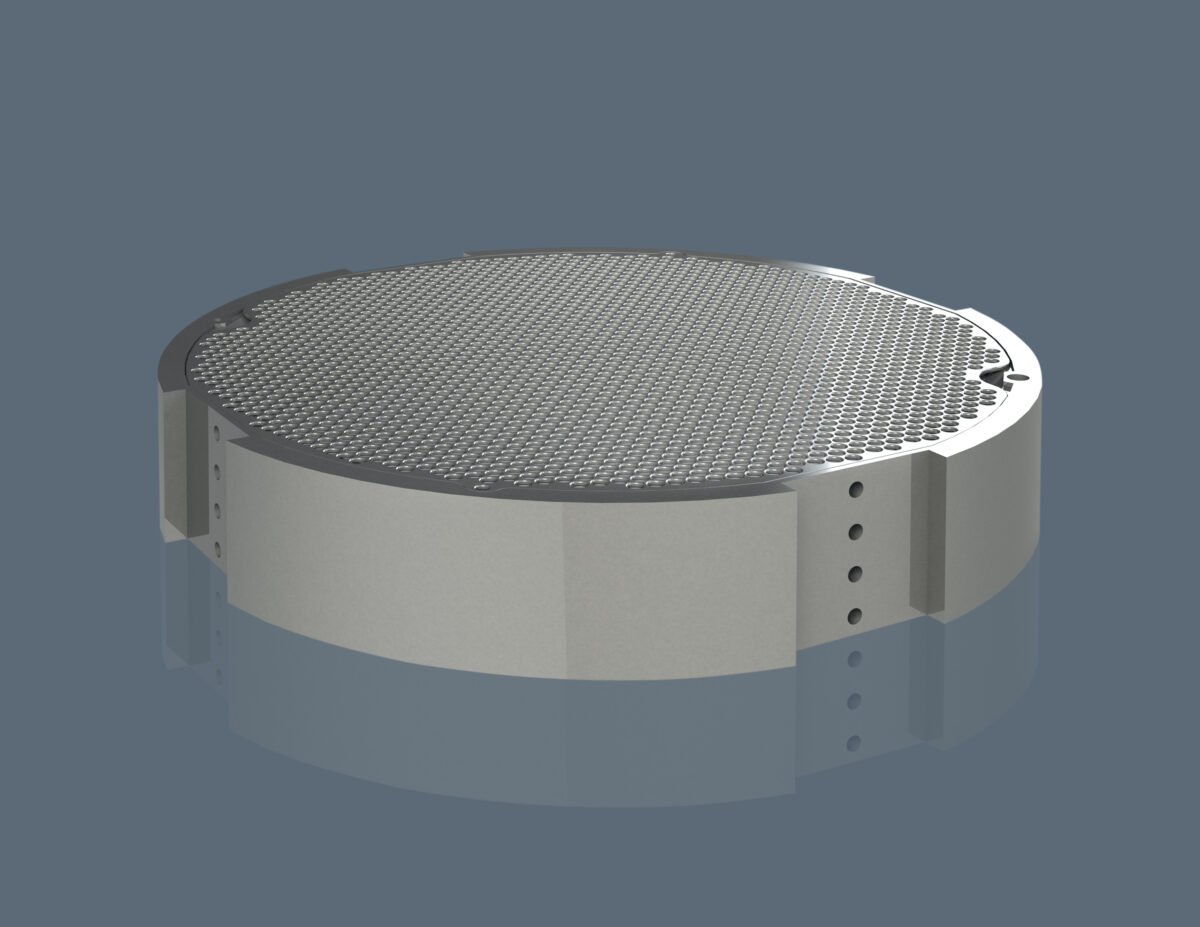

Figure 1: Rendering of Component Stack Assembly

Another important parameter to validate is the fabrication method of the stack parts. We have selected fabrication techniques that allowed us to progress rapidly within our budgetary constraints. Component testing will confirm both the electrical performance of the stack assembly and the fabrication techniques for the parts themselves.

Progress toward the component test has been positive. The insulating rings for the component testing have been ordered and should be completed in the next few weeks. By August, we should be conducting the component test of the stack assembly as shown in the rendering Figure 1.

In summary, the component testing will verify if the new designs allow us to achieve a sufficiently high voltage to reach treatment field strengths in oil. The component testing of the stack assembly parts should show that we have protected against arcing and stopped the oil circulation zones that occurred when testing previously manufactured AOT parts. Once we verify that treatment field strength can be successfully reached, we will prepare to conduct a full-size hydrostatic test targeted for mid-September.

“We have given you the technical reasons for our upcoming component test and to be followed by a hydrostatic test. The hydrostatic test is a key step showing development partners we have overcome the issues we faced in the previous demonstration project. I am pleased with the hard work and dedication of the entire QS Energy Staff as we move forward developing the AOT technology. In closing I would like to thank our investors and our board for their commitment to QS Energy,” said Cecil Bond Kyte, CEO QS Energy.

Safe Harbor Statement

Some of the statements in this release may constitute forward-looking statements under federal securities laws. Please click here for our complete cautionary forward-looking statement.

About Applied Oil Technology

QS Energy’s patented Applied Oil Technology (AOT) is a solid-state turn-key system which uses a high volt / low amp electric field to reduce crude oil viscosity. AOT installs inline on crude oil pipelines, operates unattended without interrupting pipeline flow, with full remote monitoring and control. More information is available online here.

About QS Energy

QS Energy, Inc. (OTCQB: QSEP), develops and markets crude oil flow assurance technologies designed to deliver measurable performance improvements to pipeline operations in the midstream and upstream crude oil markets. More information is available here.